Reducing construction waste: Practical strategies for North Texas remodels

- scott shipp

- Dec 17, 2025

- 11 min read

Reducing construction waste is about more than just being green—it's a direct path to a smarter, more cost-effective home build or remodel in North Texas. When you see that pile of debris not as unavoidable trash but as a stack of missed opportunities, you can uncover serious savings and end up with a better project.

Why Taming Construction Waste Matters in North Texas

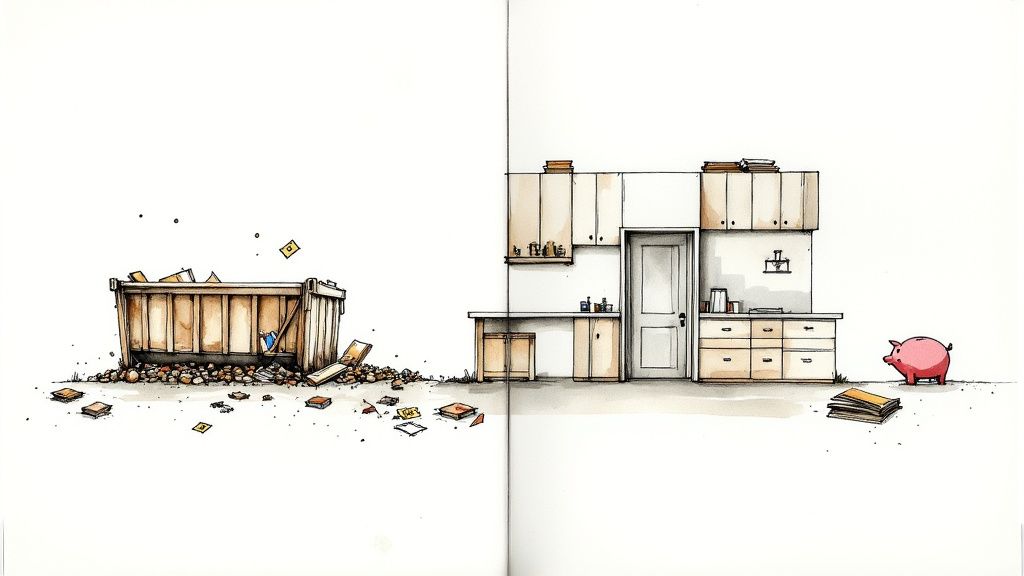

It’s a sight we all know here in Granbury or Weatherford: a massive dumpster that seems to fill up overnight the second a remodel starts. That pile isn’t just old materials; it’s a tangible symbol of hidden costs. Every piece in there represents over-ordered supplies, inefficient cuts, and disposal fees that come straight out of your budget.

With all the growth happening across North Texas, the sheer volume of construction waste is staggering. The industry globally generates over 2 billion tonnes of waste annually, a number that really puts our local responsibility into perspective. If you're interested in the bigger picture, you can explore the full findings of the research.

The Real Cost Hiding in Your Dumpster

Take a good look at that dumpster. It's often filled with perfectly good lumber, drywall offcuts, and fixtures that you paid for. Each item tossed away is a double whammy: you lose the money spent to buy it, and then you pay again to have it hauled to a landfill, with fees in North Texas often running from $400 to over $700 per dumpster.

For a family building their dream home on a plot in Glen Rose or retirees updating their forever home in Aledo, those costs add up fast. Adopting a low-waste mindset is about stopping that financial leak.

This really boils down to a few key things:

Smarter Planning: Designing rooms to fit standard material dimensions, which means fewer cuts and less scrap.

Ordering with Precision: Your builder should create a meticulous materials list. The goal is to avoid that "extra" pallet of drywall or bundle of lumber that ends up unused.

On-Site Sorting: Instead of throwing everything into one big bin, separating wood, metal, and cardboard for recycling or donation. It takes discipline but pays off.

The real shift happens when you stop seeing a waste stream and start seeing a resource stream. That leftover lumber is perfect for blocking inside walls, and old kitchen cabinets can be donated to a local charity instead of getting smashed at the dump.

Ultimately, focusing on waste reduction from day one leads to a project that's more organized, runs more smoothly, and is a whole lot easier on your wallet. It's simply about building smarter from the ground up.

Designing Your Project for Less Waste

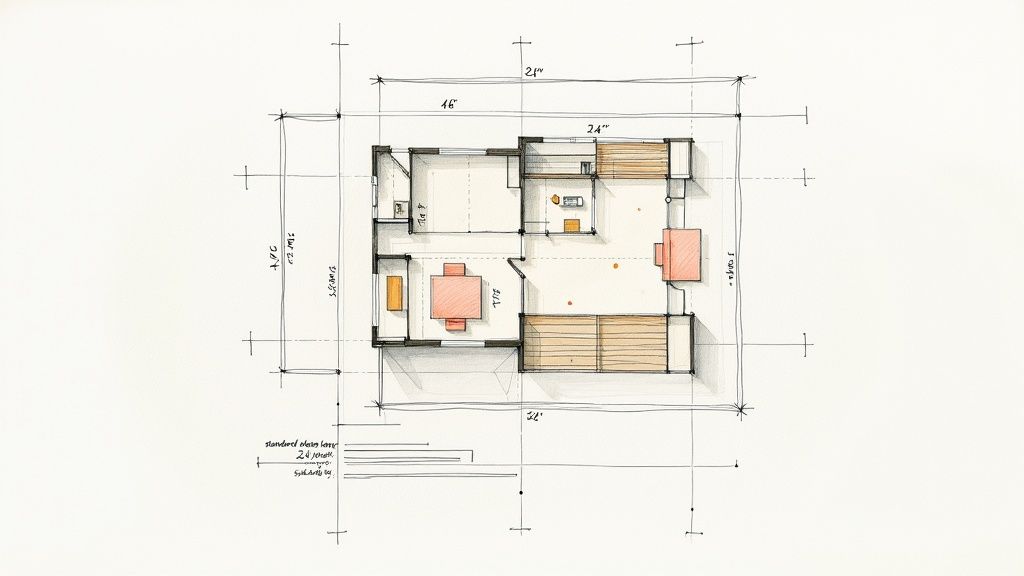

The biggest wins in cutting down construction waste happen long before anyone swings a hammer. It all starts on the drawing board. This early planning phase is your best shot at designing waste out of the project from the get-go, turning your blueprint into a powerful money-saving tool.

Getting your architect and builder on the same page early is non-negotiable. For example, why frame a room to a size that guarantees every single sheet of drywall has to be cut, creating a pile of useless offcuts? Designing rooms with dimensions that work with standard 4x8 drywall sheets or 16-foot lumber is just plain smart.

Smart Design and Material Planning

Another critical piece is a detailed materials list, what we call a 'take-off.' A good builder won't just guess. They'll meticulously calculate the exact amount of lumber, drywall, and other supplies needed for your job. This precision is what stops you from over-ordering and getting stuck with a pile of unused materials sitting in your Granbury driveway.

On a recent custom home build near Weatherford, we shifted the framing design to a 24-inch module instead of the standard 16-inch. This simple change on paper saved the homeowner thousands in lumber and drywall, resulting in a significant reduction in scrap and cost.

Here are a few things to bring up with your design and build team:

Design with Standard Sizes: Ask your designer, "How can we tweak these room sizes to better fit standard material lengths?" Think lumber, siding, and sheet goods.

Plan for Offcut Use: Work with your builder to find smart uses for the inevitable smaller pieces, like for blocking inside walls or framing out closets.

Insist on a Detailed Take-Off: Make sure your builder provides a thorough materials list. You want to avoid the "just-in-case" surplus that almost always ends up as waste.

A well-thought-out design doesn't just look good on paper; it performs efficiently on the job site. The goal is to make sure every board foot of lumber and every square foot of drywall you purchase ends up in your home, not in the landfill.

Waste Reduction Strategies Before Breaking Ground

Strategy | What It Means | Potential Savings |

|---|---|---|

Modular Design | Using dimensions that align with standard material sizes (e.g., 4x8 sheets). | Reduces cut-offs, lowering material purchase and disposal costs. |

Detailed Material Take-Off | A precise calculation of all materials needed, avoiding over-ordering. | Prevents paying for and disposing of unused surplus materials. |

Deconstruction Plan | Planning to salvage materials (cabinets, doors, flooring) before demolition. | Creates a source of free materials for reuse or items for tax-deductible donation. |

Offcut Strategy | Identifying where scrap pieces can be used for smaller tasks (e.g., blocking). | Maximizes the value of every piece of material you buy. |

Planning for Deconstruction, Not Demolition

For remodels, we need to shift our thinking from "demolition" to "deconstruction." Instead of bringing in a wrecking ball (or the sledgehammer equivalent), deconstruction is a more surgical approach. It means carefully salvaging old hardwood floors, solid-core doors, classic light fixtures, and kitchen cabinets. Your demo day becomes more of a resource hunt.

This mindset is slowly gaining ground. Right now, only about 40% of the massive 2.2 billion tonnes of annual construction waste gets a second life through reuse or recycling. But by planning for careful disassembly, some projects have cut their on-site waste by as much as 50-70%. When you plan to deconstruct, you’re turning what would have been garbage back into a genuine asset. You can discover more insights about circular construction here.

This approach isn't just good for the planet; it can lead to surprising financial perks through reuse and even tax deductions for donated items. For any family or retiree looking to remodel thoughtfully, it’s a clear win-win.

Smart Sourcing and Material Choices

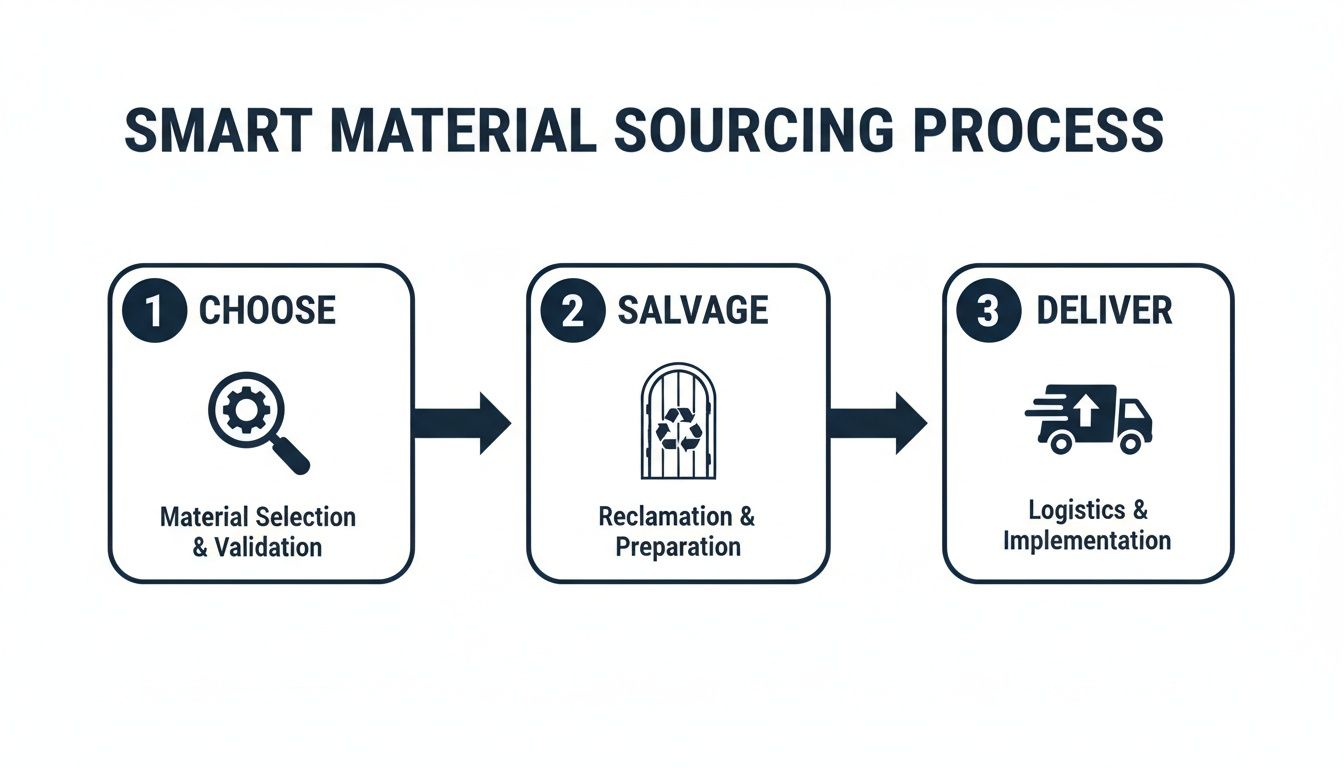

With a waste-conscious design in place, your next move is to be just as smart about the materials you choose. This is a huge opportunity to slash the amount of debris your project will generate.

Thinking about the full lifecycle of a material—from how it’s made to how it gets to your Granbury or Weatherford job site—is key.

A great first step is to buy local. Sourcing from suppliers in and around Fort Worth doesn't just put money back into our local economy; it also cuts down on the fuel and packaging waste that comes with long-haul shipping. Ask suppliers about low-packaging options or bulk deliveries. Every bit of cardboard and plastic you can avoid is a win.

The Value in Salvaged Materials

One of the most effective ways to cut waste is to work salvaged materials into your project. Instead of everything being brand new, you can find one-of-a-kind pieces that bring character while keeping items out of the landfill. This is especially true if you're remodeling an older North Texas home.

Places like the Habitat for Humanity ReStore in Fort Worth and other local architectural salvage yards are gold mines for items like:

Solid wood doors with beautiful, heavy vintage hardware.

Ornate fireplace mantels that can instantly become the focal point of a room.

Unique light fixtures with a story to tell—something you’ll never find at a big-box store.

Clawfoot tubs or pedestal sinks for a timeless bathroom aesthetic.

Giving these materials a second life isn't just about saving money. It's about weaving a piece of local history right into the fabric of your home.

Thinking Beyond the Upfront Cost

It’s easy to focus on the initial price tag, but a low-waste mindset requires looking at the bigger picture. Think about the total lifecycle cost. A classic example we see in homes from Glen Rose to Aledo is the choice between a standard wood deck and a composite one.

A pine deck might be cheaper to buy today, but composite decking—often made from recycled plastics and wood fibers—stands up to Texas weather, rot, and insects much better. You won't be staining it every year or replacing warped boards in five, which saves a ton of money and waste down the line.

This same logic applies everywhere, from long-lasting metal roofing to high-performance windows. When you invest in durability, you replace things less often. That’s the ultimate waste reduction strategy. For a deeper dive on this, check out our guide to building green custom homes in North Texas.

Just-in-Time Delivery for Material Protection

Finally, let's talk logistics. How your materials arrive on-site can make or break your waste reduction efforts. I’ve seen it happen too many times: a pallet of drywall or a stack of expensive lumber gets ruined by a sudden North Texas thunderstorm simply because it was delivered too early. Damaged goods go straight to the dumpster.

The solution is to coordinate just-in-time deliveries with your builder. This simple practice ensures materials show up right when they’re needed, not weeks in advance. It keeps the job site cleaner, protects your materials from weather and damage, and makes sure every dollar you spend ends up in your home, not in the trash.

Managing the Job Site for Minimal Waste

A clean, organized job site is more than just a preference—it’s a sign of a safe, efficient, and low-waste project. Once the first hammer swings, all that careful planning shifts from the blueprints to the boots on the ground.

The whole game changes when you stop thinking of a single, massive dumpster as the only option. Instead, the goal is to sort materials as they come off the house. It takes a little extra effort upfront but pays off big time in lower disposal fees and valuable recovered resources.

Before anyone breaks ground, have a frank conversation with your builder about their on-site waste management plan. It needs to be a real strategy, not just a vague promise to "try and recycle."

Creating an Effective On-Site Sorting System

The simplest, most effective approach is to set up separate, clearly labeled bins or dedicated piles for different materials right from the start. This makes the entire recycling and reuse process a hundred times easier.

Clean Wood: Unpainted and untreated lumber scraps are perfect for repurposing.

Metal: Things like steel studs, leftover copper wiring, and aluminum flashing are valuable commodities. Scrap yards will often pay you for them.

Cardboard: With deliveries showing up daily, cardboard can become a mountain overnight. Breaking it down and keeping it dry makes it a breeze to recycle.

Concrete and Masonry: Broken concrete from an old patio or driveway demolition can be crushed and find a new life as road base.

Intentional sourcing and handling of materials directly lead to a cleaner, more efficient project from start to finish.

The simple act of sorting opens up fantastic opportunities for reuse right here in our North Texas community. That pile of clean wood scraps from a new build in Granbury? It could be exactly what a local farmer needs for animal bedding. Those leftover, undamaged sheets of insulation from a remodel in Aledo? A local theater group could use them to build sets.

Pro Tip: Never underestimate the power of a simple tarp. A single, unexpected Texas downpour can ruin a stack of drywall or warp thousands of dollars in lumber, sending it straight to the landfill. Protecting your materials can save a small fortune in replacement and disposal costs.

Common Construction Materials and Their Local Recycling Options

Material | Local Reuse/Recycling Options | Tip for Segregation |

|---|---|---|

Clean Wood (Untreated) | Local farms for bedding/mulch, community gardens for paths, or specialty wood recyclers. | Keep separate from painted or treated wood. Nails are usually okay, but ask your recycler. |

Scrap Metal | Take to local scrap yards in Weatherford or Granbury. They often pay by weight. | Keep ferrous (steel) and non-ferrous (copper, aluminum) metals in separate piles if possible. |

Asphalt Shingles | Can be recycled into asphalt pavement. Look for specialty recyclers in the DFW area. | Must be free of other debris like wood, plastic, and flashing. |

Cardboard | City recycling programs or local drop-off centers. | Break down boxes to save space and keep them dry to maintain their value. |

Concrete & Brick | Can be crushed for aggregate or road base. Check with local landscape supply or excavation companies. | Remove rebar and other contaminants. |

Your Role in a Low-Waste Job Site

As the homeowner, your active participation can make a huge difference. Walk the site with your builder from time to time. It’s a great way to see how the sorting plan is working and spot opportunities to salvage or donate materials that might otherwise be overlooked.

Staying engaged reinforces the importance of waste reduction and helps your build team stay focused on the goal. For more tips on keeping your project on track, our whole-house renovation checklist for North Texas is a fantastic resource.

A Homeowner's Guide to North Texas Recycling Resources

Knowing how to sort your materials is half the battle. The other half is knowing exactly where to take them here in North Texas. Thankfully, our region has a growing network of resources ready to turn your project’s “waste” into a valuable commodity.

This web of local organizations and businesses across Parker, Hood, and Tarrant counties is a homeowner’s best friend during a remodel. Instead of paying hefty landfill fees, you can often donate items for a tax deduction or even sell them for scrap.

We saw this firsthand with a family in Glen Rose who recently redid their kitchen. They took the time to carefully remove their old oak cabinets, countertops, and appliances. By donating the entire set to a local Habitat for Humanity ReStore, they not only helped another family but also saved an estimated $300-$500 in dumpster and disposal fees.

Key Resources for Your Salvaged Materials

The good news is you don’t have to drive all over the DFW metroplex to find a home for your leftover materials. For most projects in the Granbury and Weatherford areas, you'll find what you need right here.

Habitat for Humanity ReStores: With locations in Fort Worth, Weatherford, and other nearby towns, ReStores are fantastic partners. They’re looking for doors, windows, cabinets, light fixtures, and working appliances. A pro tip: make sure everything is clean and pull any nails from lumber before you drop it off.

Architectural Salvage Yards: If you have something special—like antique doors, a clawfoot tub, or old-growth hardwood flooring—an architectural salvage yard is the place to go. These businesses are all about preserving local history by reselling unique building materials.

Specialized Recycling Facilities: For the heavy stuff, you’ll need a specialist. Facilities around DFW handle concrete and asphalt crushing, turning old driveways into new road base. Local scrap metal yards will even pay you for leftover steel, copper wiring, and aluminum.

Tapping into these local resources does more than just keep materials out of the landfill. You’re actively participating in a circular economy that benefits local families, saves valuable materials, and makes your own project more budget-friendly.

This local effort is part of a massive positive trend. In the U.S. alone, the construction waste market has grown to USD 44.1 billion, largely driven by the demand for sustainable building. While globally around 93% of construction waste is recovered, residential projects are where individual homeowners can make a huge, direct impact. You can learn more about the growth of construction waste recycling to see the bigger picture.

The Financial Payoff of a Low Waste Project

Every strategy we've covered, from smart design to on-site sorting, ultimately circles back to your budget. Reducing construction waste isn't just a green initiative; it’s a powerful financial lever that can create real savings and boost your project's bottom line.

Landfill "tipping fees" here in North Texas are no joke, and every ton of debris you keep out of the dumpster is cash that stays in your wallet.

For a typical new home build in Aledo or Weatherford, a disciplined approach to on-site sorting and recycling can easily save you $1,500 to $3,000 in dumpster fees alone. That's a serious return for what amounts to better planning and a little extra effort.

Tapping into New Revenue and Savings Streams

Beyond just avoiding costs, a low-waste project can open up new opportunities for savings and even generate income.

Scrap Metal Payouts: Never just toss leftover copper wiring, steel studs, or aluminum siding. Local scrap yards in the Granbury area pay for these materials, turning waste into cash.

Tax Benefits from Donations: When you salvage and donate items like old kitchen cabinets, doors, or appliances to a local Habitat for Humanity ReStore, you avoid disposal costs and may get a tax-deductible receipt.

Cutting Over-Ordering Costs: A precise material takeoff is your best friend. It stops you from buying supplies you don't need in the first place, which is pure, upfront savings.

A low-waste project isn’t about sacrifice. It’s about smart, efficient building that results in a higher-quality home and a much healthier bottom line. Every board foot saved and every fixture donated directly contributes to your project's financial success.

These small wins stack up into a significant financial advantage. Thinking this way is a huge part of maximizing your home remodel return on investment, as it makes the entire process leaner and more cost-effective.

Planning a project that's as financially savvy as it is sustainable is our specialty. If you're ready to start a conversation about your North Texas custom home or remodel, we'd be happy to share how our process can make a difference. Let's build something better, together—contact us for a free consultation.

Comments