A Homeowner's Construction Quality Control Checklist for North Texas

- scott shipp

- Jan 11

- 17 min read

Building a custom home or undertaking a major remodel in Granbury, Weatherford, or across North Texas is one of the most significant investments you'll ever make. It's an exciting journey, but how do you guarantee the final product not only matches your vision but also stands up to our unique challenges, from shifting clay soils to intense summer heat? The answer lies in a meticulous, phase-by-phase verification of every single detail. This is where a comprehensive construction quality control checklist becomes your most essential tool.

Think of it as your project's blueprint for excellence. It transforms abstract quality standards into tangible, verifiable checkpoints, ensuring nothing falls through the cracks. This guide provides a practical checklist tailored for homeowners in communities like Glen Rose and Aledo, breaking down the entire building process into manageable stages, from pre-construction planning to the final walkthrough.

You’ll learn exactly what to look for during foundation pours, framing inspections, MEP (Mechanical, Electrical, and Plumbing) installations, and all the way through to the final finishes. This detailed approach empowers you to have informed conversations with your builder, catch potential issues before they become costly problems, and ensure your custom home or remodel is built to the highest standard of craftsmanship. This checklist is your roadmap to building with confidence.

1. Foundation and Structural Integrity Inspection

The foundation is the most critical element of your home, acting as the bedrock for everything that follows. A thorough foundation inspection is non-negotiable, especially in North Texas where our soil can be unpredictable. This phase verifies that the foundation is designed and constructed to withstand local environmental factors, ensuring the long-term stability of your home.

This process involves multiple checkpoints, from initial soil analysis to post-pour assessments. Inspectors verify that the concrete mix is correct, reinforcement like rebar is properly placed, and the entire structure complies with engineering plans and local building codes. It's the first and most important step in any construction quality control checklist.

Why It's Crucial for North Texas Soil

In areas like Granbury, Weatherford, and Glen Rose, the soil can range from highly expansive clay to rocky caliche. Expansive clay soils swell significantly when wet and shrink when dry, exerting immense pressure on a foundation. Without proper design, this seasonal movement can lead to cracks, uneven settling, and significant structural damage over time.

Key Insight: A "one-size-fits-all" foundation is a recipe for disaster in North Texas. A home's foundation must be engineered specifically for the soil characteristics of its exact lot.

For example, a custom build on a Granbury lot with expansive clay should incorporate engineered solutions like moisture barriers, robust drainage systems, and potentially a post-tension slab to counteract soil movement. A home for a retiring couple on acreage in Glen Rose with varied topography might require a pier and beam foundation or drilled piers to reach stable soil layers.

Actionable Inspection Tips

To ensure your foundation is built to last, integrate these specific checks into your process:

Pre-Construction Soil Testing: Before any dirt is moved, a geotechnical engineer should perform soil borings and analysis. This report dictates the required foundation type and reinforcement needed. This can cost between $1,500 and $5,000 but is invaluable.

Pre-Pour Inspection: Schedule an inspection before the concrete is poured. The inspector will verify rebar placement, beam depth, formwork, and the installation of plumbing and vapor barriers. This is your last chance to catch mistakes before they are encased in concrete.

Post-Pour Curing and Grading: After the pour, ensure the concrete is cured correctly to achieve its designed strength. Simultaneously, verify that the surrounding grade slopes away from the foundation at a minimum of 6 inches over the first 10 feet to prevent water intrusion.

A well-executed foundation inspection provides peace of mind, protecting your investment from costly future repairs.

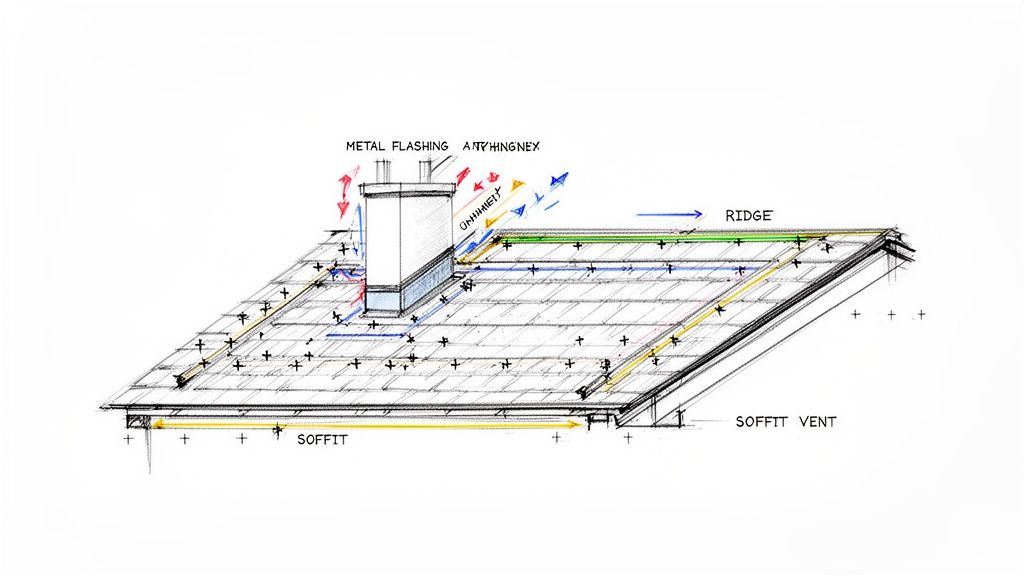

2. Roofing Material Quality and Installation Verification

In North Texas, a roof is your home's first line of defense against severe weather, from intense hailstorms to high-velocity winds. A comprehensive inspection of roofing materials and installation techniques is essential. This verification process confirms that every component, from the underlayment to the final shingle, meets manufacturer specifications and is installed to withstand our punishing local climate.

This phase of your construction quality control checklist scrutinizes flashing details, ventilation, and overall weather-sealing. It's a vital step for both brand-new custom homes and properties needing roof replacement after storm damage, ensuring long-term durability and performance.

Why It's Crucial for North Texas Weather

The weather in areas like Granbury, Weatherford, and Aledo can be extreme. Hail can shred substandard shingles, and winds common during thunderstorms can lift improperly fastened materials, leading to water damage. A properly installed roof system, designed for our region's specific wind loads and impact resistance ratings, is not a luxury but a necessity.

Key Insight: The quality of the installation is just as important as the quality of the materials. A high-end, Class 4 impact-resistant shingle will fail if it's not fastened correctly or if the flashing around chimneys and vents is compromised.

For example, a custom home on acreage in Granbury needs a roof engineered with specific fastening patterns and ventilation to handle open-area wind exposure. Families choosing materials should consider Class 4 shingles, which often provide insurance discounts and can withstand hail up to 2 inches in diameter. While they may cost 10-20% more than standard shingles, the long-term savings and protection are significant.

Actionable Inspection Tips

To guarantee your roof is built to withstand the elements, ensure these checks are part of your quality control process:

Material Verification: Before installation begins, confirm that the delivered materials (shingles, underlayment, flashing) match the project specifications. Document lot numbers for warranty purposes.

Installation Oversight: During installation, verify the use of the correct number and type of fasteners per shingle, as specified by the manufacturer for high-wind areas. Check that flashing is correctly installed around all roof penetrations, valleys, and edges.

Ventilation and Sealing: A properly ventilated attic is crucial in the Texas heat to prevent moisture buildup and reduce cooling costs. Ensure soffit and ridge vents are clear and provide balanced airflow. All seams and nail penetrations should be perfectly sealed.

A rigorously inspected roof provides not only shelter but also confidence.

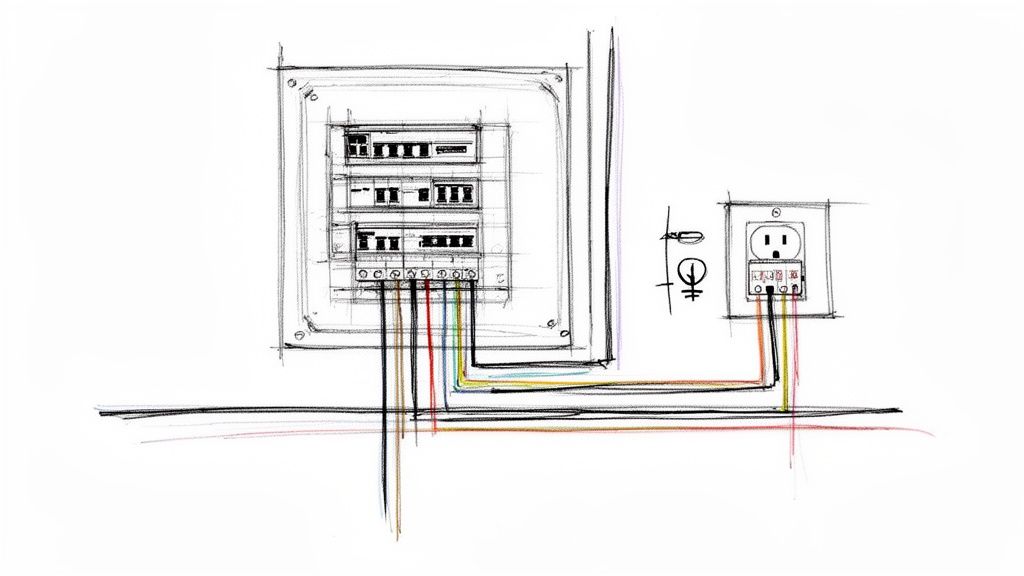

3. Electrical System Code Compliance and Safety Testing

The electrical system is the central nervous system of your home, powering everything from lighting to smart home technologies. A rigorous inspection of its code compliance and safety features is essential to prevent fire hazards and ensure reliable performance. This phase verifies that every component, from wiring gauge to breaker sizing, is installed correctly according to the National Electrical Code (NEC) and local North Texas requirements.

This isn't just about making sure the lights turn on; it's a critical safety gate in any construction quality control checklist. Inspectors confirm proper grounding, GFCI/AFCI protection, and safe installation practices, especially in custom builds with unique power demands for features like outdoor kitchens, pools, or workshops.

Why It's Crucial for Custom North Texas Homes

Custom homes in Granbury and Weatherford often feature complex electrical loads that go beyond standard construction. Elements like pools, extensive outdoor lighting for pergolas, and dedicated circuits for a workshop on your acreage demand meticulous planning and installation. A failure to correctly implement these systems can lead to overloaded circuits, equipment damage, and serious safety risks.

Key Insight: The electrical plan for a custom home must be as unique as its architectural design, accounting for every specific power requirement and ensuring it exceeds minimum code standards for safety and future-proofing.

For example, a project featuring an outdoor living space with a pool in Aledo requires multiple, dedicated GFCI-protected circuits to ensure safety around water. A family building a barndominium might need 240V outlets for welding equipment. A whole-home remodel in a historic Glen Rose property often necessitates a complete electrical service upgrade to safely support modern appliances and lighting.

Actionable Inspection Tips

To guarantee a safe and reliable electrical system, incorporate these specific checks into your building process:

Rough-In Electrical Inspection: This is a crucial pre-drywall checkpoint. An inspector must verify that all wiring is correctly routed, boxes are securely mounted, and wire gauges match the circuit breaker ratings. This is the last opportunity to see the "bones" of the system.

GFCI and AFCI Testing: At the final inspection, every Ground Fault Circuit Interrupter (GFCI) outlet near water sources and Arc Fault Circuit Interrupter (AFCI) breaker/outlet must be manually tested to confirm they trip correctly, providing critical protection against shock and fire.

Verify Proper Grounding and Bonding: The inspector should confirm the entire system is properly grounded. For homes with pools or outdoor metal structures in North Texas, this includes verifying the equipotential bonding grid, which prevents dangerous voltage differences between conductive surfaces.

A meticulous electrical inspection is a non-negotiable step that protects your home and family.

4. HVAC System Performance and Ductwork Verification

In North Texas, a high-performance HVAC system isn't a luxury; it's an absolute necessity. Verifying your heating, ventilation, and air conditioning system's performance is a critical phase in a construction quality control checklist, ensuring it can handle scorching summers in Weatherford and chilly winter mornings in Glen Rose. This inspection confirms the system is installed correctly, sized appropriately, and operates at peak efficiency.

The process goes beyond simply turning the unit on. It involves a detailed check of ductwork for leaks, verifying correct refrigerant levels, and balancing airflow to every room. Proper verification prevents common issues like uneven temperatures, high energy bills, and premature system failure.

Why It's Crucial for North Texas Climate Control

The extreme temperature swings in North Texas place enormous demands on an HVAC system. A system that is improperly sized or has leaky ducts will struggle to keep up during a 100-degree August day, running constantly while failing to adequately cool the home. This leads to excessive energy consumption and unnecessary wear and tear.

Key Insight: The ductwork is the circulatory system of your home's climate control. Even the most expensive, high-efficiency HVAC unit will perform poorly if the ducts are leaky, poorly designed, or uninsulated.

For instance, a multi-story custom home in Granbury needs a zoned system to provide consistent temperatures on each floor. Without proper verification, the upstairs might remain hot while the downstairs is freezing. Families with young children or aging parents at home will particularly value this consistent comfort. When adding an extension to an existing home, simply extending old ductwork will strain the existing unit and compromise comfort throughout the house.

Actionable Inspection Tips

To guarantee your HVAC system delivers reliable comfort and efficiency, incorporate these specific checks:

Duct Leakage Test (Blower Door Test): Before the drywall is installed, have a third party conduct a blower door test. This test pressurizes the duct system to precisely measure air leakage, identifying any disconnected joints or unsealed seams that need to be fixed.

System Commissioning: Schedule a final commissioning visit with your HVAC contractor before moving in. They should test the system in both heating and cooling modes, measure refrigerant charge, and verify that airflow from each vent matches the design specifications.

Verify Equipment and Documentation: Ensure all installed equipment matches the models and specifications in your contract. Request all manufacturer documentation and proof of warranty registration.

A meticulously verified HVAC system ensures your home remains a comfortable sanctuary year-round. You can explore a detailed guide to learn more about how to insulate HVAC ducts for comfort and savings in North Texas.

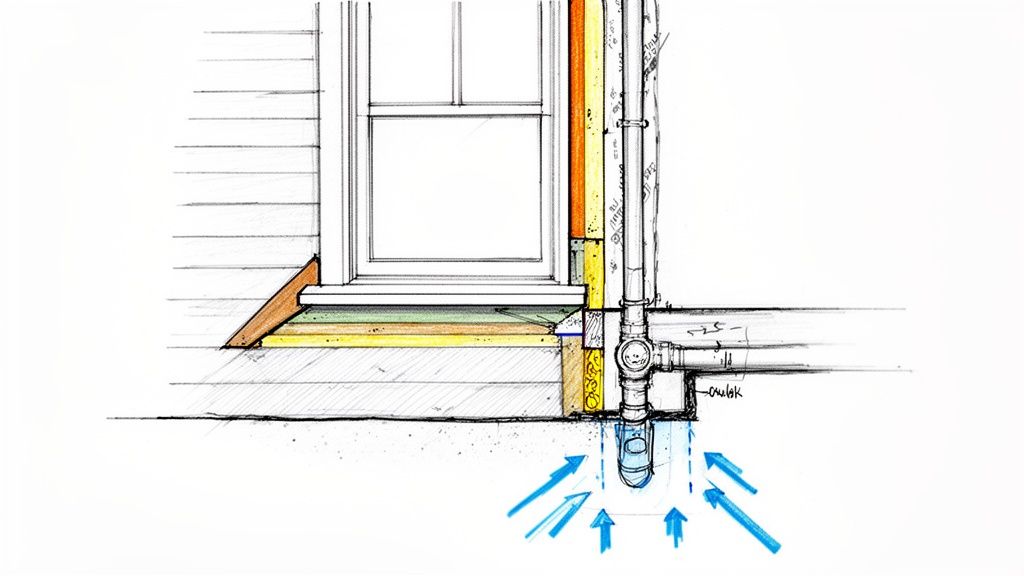

5. Plumbing System Pressure Testing and Code Verification

A home's plumbing system is its circulatory network, and even a minor failure can lead to catastrophic water damage and mold growth. A comprehensive inspection is a critical phase in a construction quality control checklist, verifying that every pipe, valve, and fixture operates flawlessly and meets strict building codes. This goes far beyond just turning on a faucet.

This process involves pressure testing the water supply lines to expose hidden leaks, confirming drain systems have the proper slope, and verifying that installations like water heaters and fixtures are correct. It’s about ensuring the long-term reliability of the system hidden behind your walls.

Why It's Crucial for Remodels and New Builds

Whether it's a whole-home remodel in Weatherford requiring an upgraded water supply for multiple new bathrooms, or a custom barndominium in rural Parker County, plumbing integrity is paramount. In remodels, new plumbing is often tied into existing lines, creating potential failure points if not executed perfectly. For new construction, ensuring the system is designed to handle the home's specific demands prevents future issues.

Key Insight: The most expensive plumbing mistake is the one you can't see. Verifying the system before the drywall goes up is the single most important step to prevent future leaks and water damage.

For example, a kitchen remodel that moves a sink to a new island involves running new supply and drain lines. Verifying these new connections with a pressure test is non-negotiable. Similarly, a guest house in Granbury needs its own properly sized water heater and septic-compatible drainage, all of which must be inspected and approved.

Actionable Inspection Tips

To ensure your plumbing system is leak-free and built to last, incorporate these specific checks into your project:

Rough-In Pressure Testing: Before any insulation or drywall is installed, the plumbing contractor must perform a pressure test on the water supply lines. Request a written report showing the system held a specific PSI (pounds per square inch) for a required duration without any drop in pressure.

Verify Drain, Waste, and Vent (DWV) Systems: Walk the site with your builder to visually inspect all drain lines. Confirm they have a consistent, proper slope (typically 1/4 inch per foot) to ensure waste flows correctly and to prevent blockages.

Fixture and Valve Verification: After walls are closed and fixtures are set, test every single one. Turn on all faucets and showers, flush all toilets, and run the dishwasher. Check for leaks at the fixture and at the shut-off valves under sinks and behind toilets, ensuring every valve is accessible.

A meticulous plumbing inspection protects your home from the silent threat of water damage, ensuring your system performs reliably for decades.

6. Drywall Installation, Finishing, and Texture Quality Control

Once the framing and mechanical systems are in place, the focus shifts to the interior surfaces that you will see and touch every day. Drywall installation and finishing are crucial for a high-end feel, transforming the raw structure into refined living spaces. This inspection phase ensures that drywall sheets are hung correctly, joints are seamlessly taped and mudded, and the final texture is applied with professional consistency.

This is a detail-oriented stage where craftsmanship truly shows. A meticulous approach here prevents visible seams, nail pops, and uneven surfaces that can detract from the beauty of your home. This step is a vital part of any construction quality control checklist because it directly impacts the final aesthetic of the project.

Why It's Crucial for a Premium Finish

In custom homes across Granbury and Aledo, a flawless, smooth finish is often the standard. Imperfections in drywall are magnified by natural light streaming through large windows and by modern lighting designs. Even minor flaws like visible joints or uneven texture can make an otherwise perfect room feel unfinished.

Key Insight: The quality of the drywall finish is a direct reflection of the builder's commitment to detail. It's a non-negotiable step for achieving a luxury aesthetic in a custom home or high-end remodel.

For example, a whole-home remodel in Weatherford aiming to update a dated interior will rely heavily on pristine drywall work to elevate its perceived value. A Level 4 or Level 5 smooth finish, which requires multiple coats of joint compound and extensive sanding, creates a perfect canvas for paint and decor. This finish can add $1.00-$2.00 per square foot to the cost but signals superior quality to anyone who walks through the door.

Actionable Inspection Tips

To ensure your interior walls and ceilings are immaculate, incorporate these specific checks into your process:

Pre-Mudding Inspection: Before any tape or mud is applied, walk through and inspect the hung drywall. Check that screws or nails are set at the correct depth (not breaking the paper) and that there are no large gaps between sheets.

Full-Light Inspection: After taping and mudding but before primer, conduct an inspection using bright, angled light. Hold a work lamp close to the wall and shine it across the surface. This technique, called "raking light," will reveal any ridges or uneven areas that are invisible in flat, ambient light.

Texture Sample Approval: If your home will have a textured finish (like knockdown), insist on a sample board for approval. The crew should create a 2x2 foot sample, allowing you to sign off on the consistency and style before they apply it to the entire house.

A rigorous drywall inspection ensures the interior surfaces of your home are as well-crafted as its hidden structure.

7. Exterior Envelope Inspection (Windows, Doors, Siding, Waterproofing)

The exterior envelope, or building shell, is your home's primary defense against the elements. This inspection phase is a comprehensive review of windows, doors, siding, and the critical underlying waterproofing systems. It ensures your home is a sealed, protected environment, ready to handle the intense North Texas climate from scorching sun and high winds to driving rain.

A properly sealed envelope is crucial for preventing water intrusion, which can lead to mold, rot, and structural damage. This step is a vital part of any construction quality control checklist, verifying that every seam, joint, and penetration is meticulously detailed to create a continuous barrier.

Why It's Crucial for North Texas Weather

In areas like Weatherford and Aledo, homes face a barrage of weather extremes. Intense UV exposure can degrade improper caulking and siding finishes prematurely, while sudden, heavy rainfall can exploit the smallest installation flaw. For additions and remodels, integrating the new envelope seamlessly with the existing structure is paramount.

Key Insight: The performance of your exterior envelope isn't just about the quality of the siding or windows; it's about the quality of the installation and the integration of the underlying water-resistive barriers and flashing.

For example, a modern farmhouse build in Granbury using James Hardie siding requires specific flashing details around windows and trim to direct water out and away from the wall cavity. On an addition project, tying the new house wrap into the old requires careful layering and taping to create a continuous moisture barrier. Overlooking these details can turn a beautiful exterior into a costly liability.

Actionable Inspection Tips

To ensure your home's exterior is completely sealed and weather-tight, incorporate these checkpoints:

Pre-Siding Inspection: Before any siding, brick, or stone is installed, inspect the house wrap. Verify all seams are taped correctly with manufacturer-approved tape and that the wrap is installed shingle-style (upper layers overlapping lower layers).

Window and Door Flashing: Check that every window and door opening is properly flashed before the units are installed. This includes a sloped sill pan to drain incidental water, as well as jamb and head flashing integrated with the house wrap. This is your most critical defense against leaks.

Penetration Sealing: Every place a pipe, wire, or vent penetrates the exterior wall must be sealed. Confirm that appropriate materials are used, such as specialized flashing boots or high-quality sealant.

Material Integration: For homes with mixed materials, like a Weatherford home featuring both stone and stucco, pay close attention to the transition points. Ensure proper expansion joints and flashing are used to accommodate the different materials and prevent cracking and water entry.

A meticulous exterior envelope inspection is fundamental to building a durable, energy-efficient, and low-maintenance home.

8. Paint Quality, Coverage, and Color Consistency Verification

Paint is the final aesthetic layer of your home, transforming raw materials into a finished, personalized space. This inspection verifies that the paint application meets high standards for quality, from meticulous surface preparation to the final, flawless coat. It ensures that colors are consistent, coverage is complete, and the finish is free from imperfections like drips, runs, or lap marks.

As one of the last steps, the paint job is also one of the most scrutinized elements by homeowners. A high-quality paint finish is a clear indicator of a builder's attention to detail and is a critical component of any comprehensive construction quality control checklist, directly impacting your daily satisfaction with your new home.

Why It's Crucial for a High-End Finish

In North Texas custom homes, particularly in communities like Granbury and Weatherford, paint does more than just add color; it defines the home's character. Homeowners often select sophisticated color palettes and premium finishes that demand expert application. A rushed or poorly executed paint job can undermine the quality of the materials and craftsmanship underneath.

Key Insight: The final paint finish is a direct reflection of the builder's commitment to quality. Imperfections here often signal that shortcuts may have been taken elsewhere.

For example, a whole-home remodel in Aledo aiming for a modern, clean aesthetic will rely on perfectly smooth walls and crisp, straight lines at trim and ceiling transitions. A specialty finish on an accent wall in a primary suite requires precise technique. This verification step ensures the visual impact matches the design intent.

Actionable Inspection Tips

To guarantee a beautiful and durable paint finish, incorporate these specific checks into your final walkthroughs:

Approve Samples in Situ: Before full application, review paint samples on the actual walls of your home. View them in both natural daylight and with the installed artificial lighting to ensure the color appears as you envisioned.

Verify Surface Preparation: A perfect finish starts with a perfect surface. Request that your builder allows for an inspection after wall preparation (sanding, filling, cleaning) but before the primer is applied.

Inspect Under Multiple Lighting Conditions: Schedule your final paint walkthrough during the day. Systematically inspect each room, then repeat the process with the lights on to catch imperfections.

Check for Exterior Durability: For homes in North Texas, ensure the exterior paint is a high-quality formulation designed to withstand intense sun and heat. This prevents premature fading, chalking, and peeling.

Request Labeled Touch-Up Paint: Ask for a small, labeled container of each color and finish used in your home. This makes future touch-ups for minor scuffs and dings seamless.

A meticulous paint inspection ensures the final look and feel of your home is exactly as you dreamed.

8-Point Construction Quality Control Comparison

Title | Implementation complexity | Resource requirements | Expected outcomes | Ideal use cases | Key advantages |

|---|---|---|---|---|---|

Foundation and Structural Integrity Inspection | High — requires geotechnical input and structural verification | Soil borings, foundation engineers, heavy equipment, drainage materials | Stable foundation, reduced settling, code compliance | New custom homes on clay/caliche, rural sites, barndominiums | Prevents structural failure, protects investment, improves longevity |

Roofing Material Quality and Installation Verification | Medium–High — weather and manufacturer-critical | Quality roofing materials, certified roofers, flashing, ventilation components, testing | Weatherproof roof, hail/wind resistance, insurance validation | New roofs, insurance claim repairs, storm-prone areas | Prevents leaks, extends roof life, supports claims coverage |

Electrical System Code Compliance and Safety Testing | High — complex NEC requirements and safety testing | Licensed electricians, testing equipment (multimeters, AFCI/GFCI testers), quality components | Safe power distribution, NEC compliance, reliable circuits | Custom homes, pools/outdoor systems, major remodels | Reduces fire/shock risk, ensures inspections pass, future-proofing |

HVAC System Performance and Ductwork Verification | Medium — requires balancing and commissioning | HVAC contractor, testing gear (manometers, blower door), sealed/insulated ducts | Efficient climate control, balanced airflow, lower energy use | Multi-story homes, additions, energy-sensitive rural properties | Improves comfort, reduces energy costs, enhances IAQ |

Plumbing System Pressure Testing and Code Verification | Medium — pressure/flow testing and venting checks | Licensed plumbers, pressure-testing equipment, proper piping (PEX/copper), access points | Leak-free supply/drainage, code compliance, reliable hot water | Kitchens/bath remodels, new homes, pools/outdoor features | Prevents water damage, avoids backups, extends system life |

Drywall Installation, Finishing, and Texture Quality Control | Medium — labor-intensive, skill-dependent | Experienced tapers/finishers, proper lighting, finishing materials | Smooth, durable interior surfaces ready for paint | High-end interiors, whole-home remodels, open-concept spaces | Delivers visible quality, prevents cracks, improves final aesthetics |

Exterior Envelope Inspection (Windows, Doors, Siding, Waterproofing) | High — requires detailed flashing and continuity checks | Skilled installers, house wrap, flashing, sealants, precise flashing details | Weather-resistant envelope, reduced air/water intrusion, energy savings | New construction, additions, remodels in variable climates | Prevents moisture damage, increases durability, improves efficiency |

Paint Quality, Coverage, and Color Consistency Verification | Low–Medium — prep-critical though straightforward | Quality paint, experienced painters, controlled application conditions | Consistent color/finish, durable surfaces, ready-for-occupancy look | Final finishes on all builds and remodels, accent/features | Enhances homeowner satisfaction, protects surfaces, cohesive aesthetics |

Turning Your Checklist into a Beautifully Built Home

We’ve journeyed through the intricate phases of building a home, from the raw earth of the foundation to the final coat of paint. This construction quality control checklist is more than just a series of tasks; it's a strategic roadmap. It’s your framework for ensuring that the home you’ve envisioned is the home that gets built, with every detail executed to the highest standard.

Understanding these critical checkpoints empowers you to engage more effectively with your builder. It transforms your role from a passive observer into an informed partner. You can now walk your Granbury or Weatherford job site with a discerning eye, asking specific, intelligent questions about pressure tests, flashing installation, and drywall finishing techniques. This knowledge builds confidence and fosters a transparent, collaborative relationship with your construction team.

From Checklist to Craftsmanship

The true value of a construction quality control checklist is not in the document itself, but in the culture of excellence it represents. It’s about a shared commitment between you and your builder to never cut corners.

It’s Proactive, Not Reactive: Quality control is about preventing mistakes by verifying work at each critical stage. Catching a plumbing leak during a pressure test is far better than discovering it after the custom cabinetry is installed.

It Protects Your Investment: A rigorous quality control process is your best insurance policy, safeguarding the structural integrity, safety, and long-term value of your property against the unique challenges of North Texas soil and weather.

It’s the Foundation of Trust: A builder who not only welcomes but actively uses a detailed checklist demonstrates a commitment to transparency and craftsmanship. This process builds a foundation of trust that is just as important as the concrete slab your home rests upon.

Think of this checklist as the bridge between your dream and its physical reality. It ensures that the structural components you can't see are just as sound as the beautiful finishes you will enjoy every day. From ensuring the electrical panel is safely wired to verifying the HVAC system is balanced for our hot Texas summers, each step is a building block toward a safe, comfortable, and durable home.

Ultimately, a well-executed construction quality control checklist is the signature of a superior build. It’s the difference between a house that simply meets code and a home that is built to last for generations. By embracing this detailed approach, you are not just overseeing a project; you are actively curating the quality of your future life in your new North Texas home.

Ready to build a home where this level of detail is the standard, not the exception? The team at Gemini Homes integrates a rigorous construction quality control checklist into every custom home, remodel, and outdoor living project we undertake in Granbury and the surrounding North Texas communities. Contact us today to discuss how our commitment to craftsmanship can bring your vision to life.

Comments